Home \\ Sustainability \\

CT Point developed a coherent sustainability journey, focuses on six priority areas where we can accelerate progress, through targeted investment in capital and resources, with the goal of reducing our emissions by 50% for Scope1,2 and 3, aligned with keeping the temperature rise below 1.5°, in accordance with the SBTi and contributing to the generation of global positive change, assuming a clear environmental and social responsibility.

Climate change is impacting human lives and health in a variety of ways. It requires actions to reduce energy demand and switch energy systems from fossil fuels to renewable energy.

Climate change is impacting human lives and health in a variety of ways. It requires actions to reduce energy demand and switch energy systems from fossil fuels to renewable energy.

Water is a precious resource and as a textile manufacturer we use lot of water for dyeing processes. We are putting our effort to find new production and organizational solutions which guarantee lower water consuption.

We have significantly expanded our sustainable threads range including 100% recycled polyester threads both twisted and braided and sales are growing rapidly account in year 2022 for 4% of our total sales. Our key target is to yearly increase sustainable threads (both recycled or biobased) within our products range.

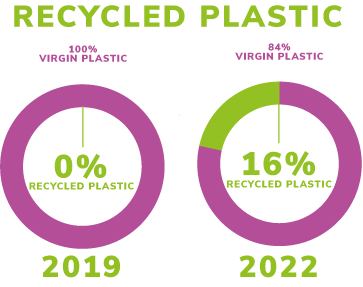

Our goal is all about finding ways to “close the loop,” eliminate waste, and source materials from the disposed-of “waste” generated by the same system. We aim at increasing use of recycled materials or enhancing reclying practises. Packaging has a key role to decrease our overall indirect emissions. We are committed to shift towards circularity through product innovation and packaging solutions. Over the next years we will start pilot projects working downstream with our customers towards a reuse paradigm called “king spools loop towards zero waste”. By applying this paradigm based on 3 reuse, we will reduce our emisions by an additional 20%.

Chemical products are high riskly for our environment, that is why we think it is vital to eliminate toxic and harmful substances from our production cycles in line with the ZDHC (Zero Discharge of Hazadous Chemicals) roadmap to Zero Programme.

![]()

No harmful substances in our products certified according to the OEKO-TEX 100 standard.

![]()

Environmental management system certification according to the UNI EN ISO 14001: 2015 standard, according to rules for effective management with reference to significant environmental aspects.

![]()

Compliance with the European Reach regulation on the use of non-hazardous chemicals.

![]()

This certification ensures our customers that our products are not only made with recycled materials, but also produced in an ethical and environmentally friendly way.